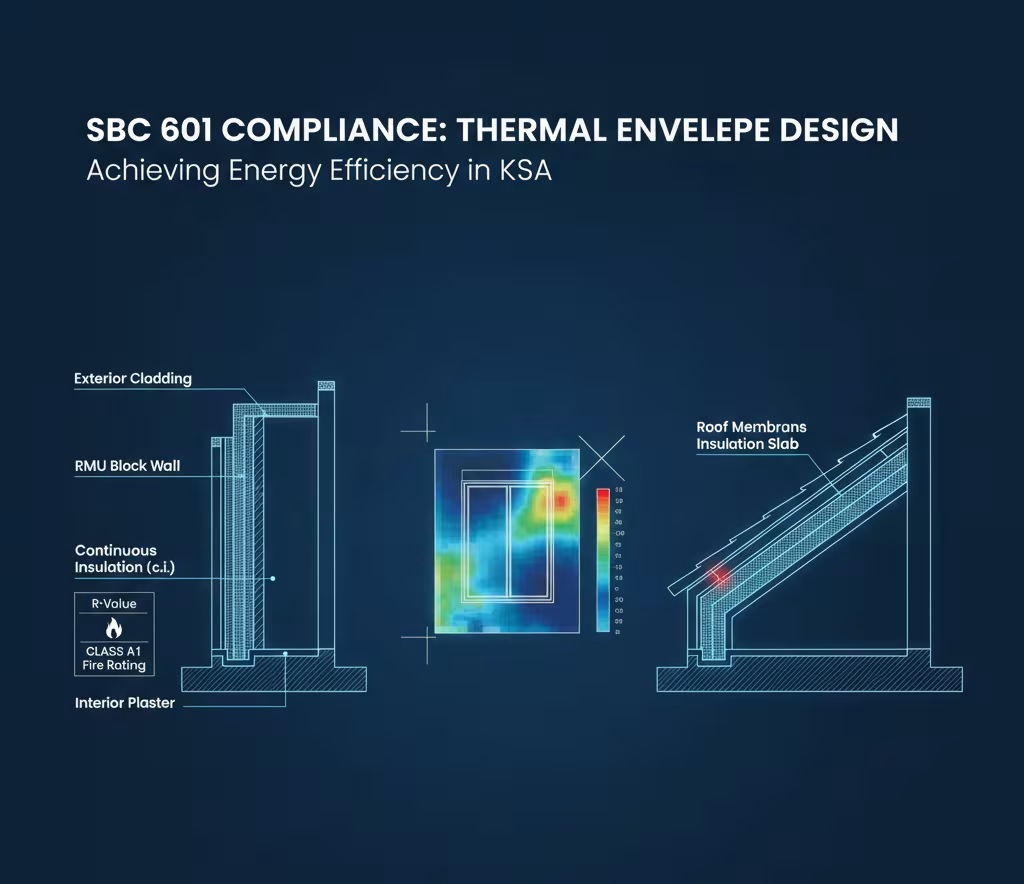

The Saudi Energy Conservation Code (SBC 601) represents a fundamental shift in KSA construction, mandating strict minimum energy-efficiency standards for the built environment. For architects and specifiers, compliance goes beyond simple adherence—it's an opportunity to design high-performance, sustainable, and lower-operating-cost structures. The most critical component for meeting SBC 601's demands is the building envelope, with insulation choice being paramount.

The Mandate: Understanding SBC 601

SBC 601 establishes minimum energy efficiency requirements for the design and construction of new non-low-rise buildings and their systems (a separate code, SBC 602, often covers low-rise residential). Its core focus is limiting thermal energy transfer to mitigate the extreme cooling load in the Kingdom's climate.

Key Compliance Metrics

- Maximum U-Value / Minimum R-Value: This is the most direct requirement. SBC 601 specifies a maximum Overall Heat Transfer Coefficient (U-Value) for opaque elements (walls, roofs, floors) and fenestration. Conversely, it mandates a minimum Thermal Resistance (R-Value) for insulation. These values vary based on the building type and the specific Climate Zone of the project location. Architectural Action: You must refer to the SBC 601 tables (e.g., Chapter 5) for the exact R-value required for your wall or roof assembly in your specific zone.

- Continuous Insulation (c.i.): The code emphasizes minimizing thermal bridging (heat transfer through non-insulated components like studs or fasteners). This often necessitates the use of continuous insulation outside the building structure.

Selecting Compliant Materials: Beyond R-Value

Achieving the required R-Value is only the first step. The choice of material must align with installation realities, durability needs, and other building codes (like SBC 601 for Fire).

| Insulation Material Type | Common Material Examples | SBC 601 Consideration | Strategic Application |

|---|---|---|---|

| Rigid Boards | Polyisocyanurate (PIR), Extruded Polystyrene (XPS) | High R-per-inch. Excellent for achieving high R-values in limited space. | Best for continuous insulation layers in façades and below-grade walls. |

| Fibrous Batts/Rolls | Mineral Wool (Rockwool/Glasswool) | Cost-effective when filling cavity space. High fire resistance (A1). | Ideal for use within wall cavities or non-ventilated attic spaces. |

| Spray/Monolithic | Polyurethane Foam (PU), Perlite-based Plaster | Seamless application. Eliminates thermal bridging risk at joints. | Excellent for complex shapes, curved surfaces, and retrofitting, ensuring a perfect thermal envelope. |

Certification and Documentation

SBC 601 is strict on proof of performance:

- R-Value Certification: Manufacturers must provide documentation verifying the declared R-Value. For blown-in or sprayed insulation, the installer must certify the installed density, thickness, and coverage area.

- Protection: Insulation applied to the exterior of foundation walls must have a rigid, opaque, and weather-resistant protective covering to maintain thermal performance.

The Architect's Checklist for SBC 601 Insulation

Meeting the SBC 601 mandates requires a deliberate approach in the design phase:

- Identify the Climate Zone: Determine the precise climate zone for the project to confirm the minimum required R-values for roofs, walls, and floors.

- Calculate the Assembly U-Value: Use calculation methods to confirm the total U-Value of the proposed wall or roof assembly (including air films, plaster, blocks, and insulation) meets or is lower than the SBC 601 maximum.

- Specify Continuous Insulation: Where required, specify materials that function as a continuous barrier (c.i.) to minimize thermal bridging, which is a common point of code failure in panelized systems.

- Detail Installation for Longevity: Design flashings, mechanical penetrations, and joints to protect the insulation from moisture, solar degradation, and physical damage, ensuring the specified R-value is maintained over the building's life.

Comments